Sat 24th January 2026

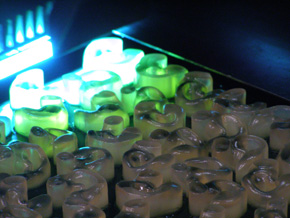

Ear Mould TechnologyWe manufacture using the latest 3D laser scanning, CAD design and 3D printing processes. Using a highly accurate laser scanner, an image of the ear impression is scanned directly into the CAD software. This is then used to create the ear mould. Scans are stored securely on our system and can be re printed avoiding the need to regularly recall patients.

Our advanced design software applies the traditional wax coat in a more homogenous way. Any faults in the impression can be repaired by the computer software before the design process begins. This high capability system allows us to produce ear moulds of unsurpassed quality and fit and unlike other manufacturers, we do not charge a premium for this service.

|

Reprinted Ear Moulds - CLICK HERE TO ORDER3D printing technology produces excellent results. The ear mould matches the fit of the original impression as closely as possible, providing optimum benefit and comfort. Advanced features, such as power venting, can now be incorporated into the ear moulds, something that has not been possible using traditional manufacturing methods.

Exact replacement ear moulds can be reproduced quickly and accurately. Any adjustments can be made using the scanned image, which we store on our system for 6 months after the production of the original ear mould. This is just the beginning. We are continuing to work with our partners to produce new materials and provide further benefits to both audiologists and their patients.

|